Table of Contents

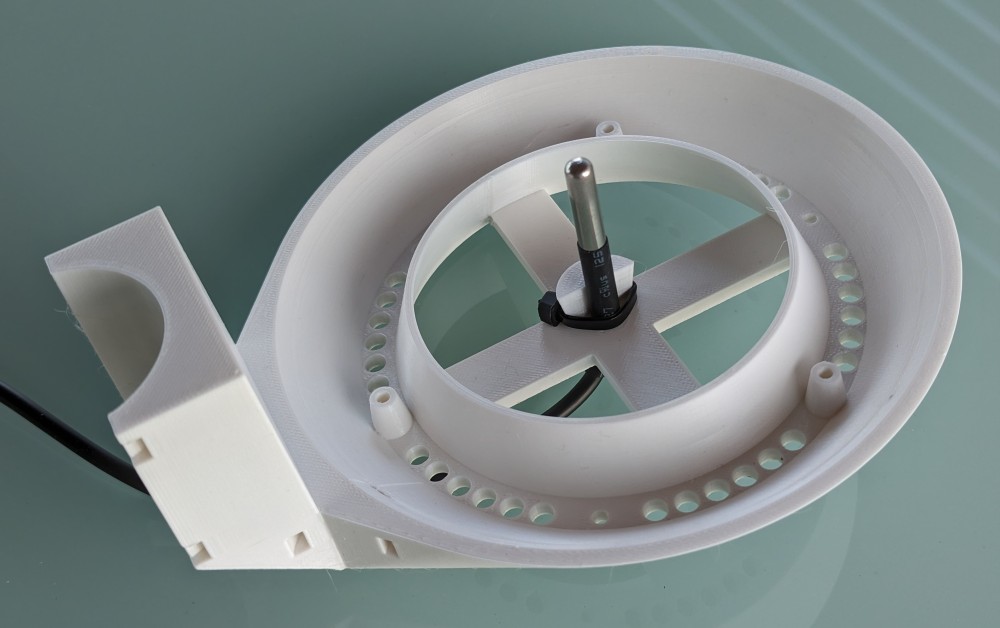

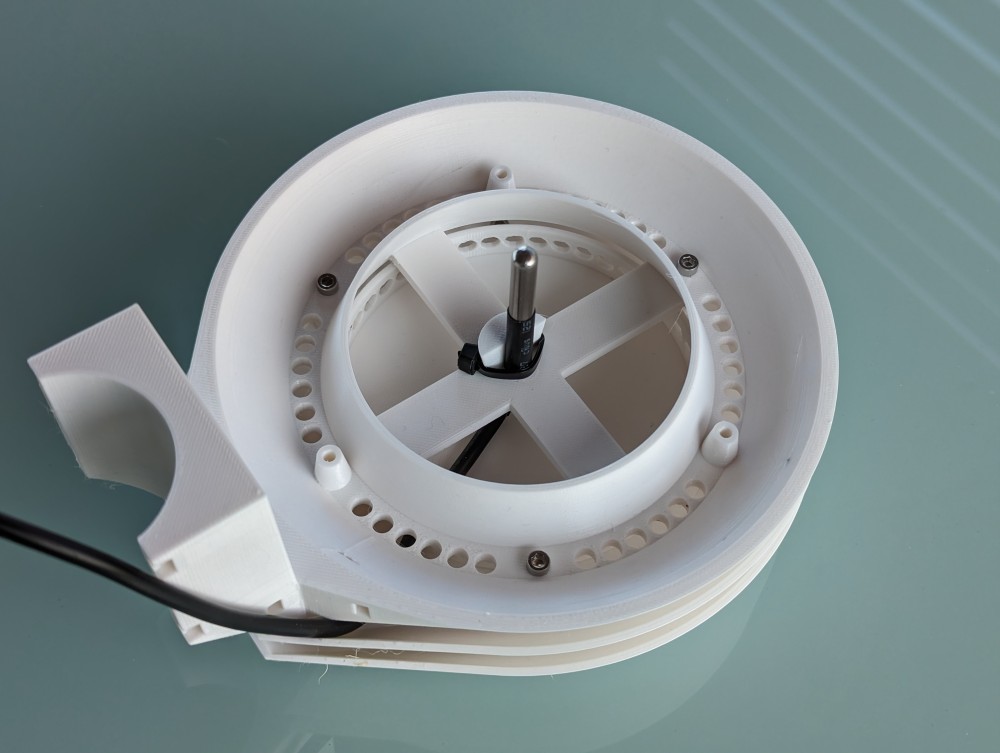

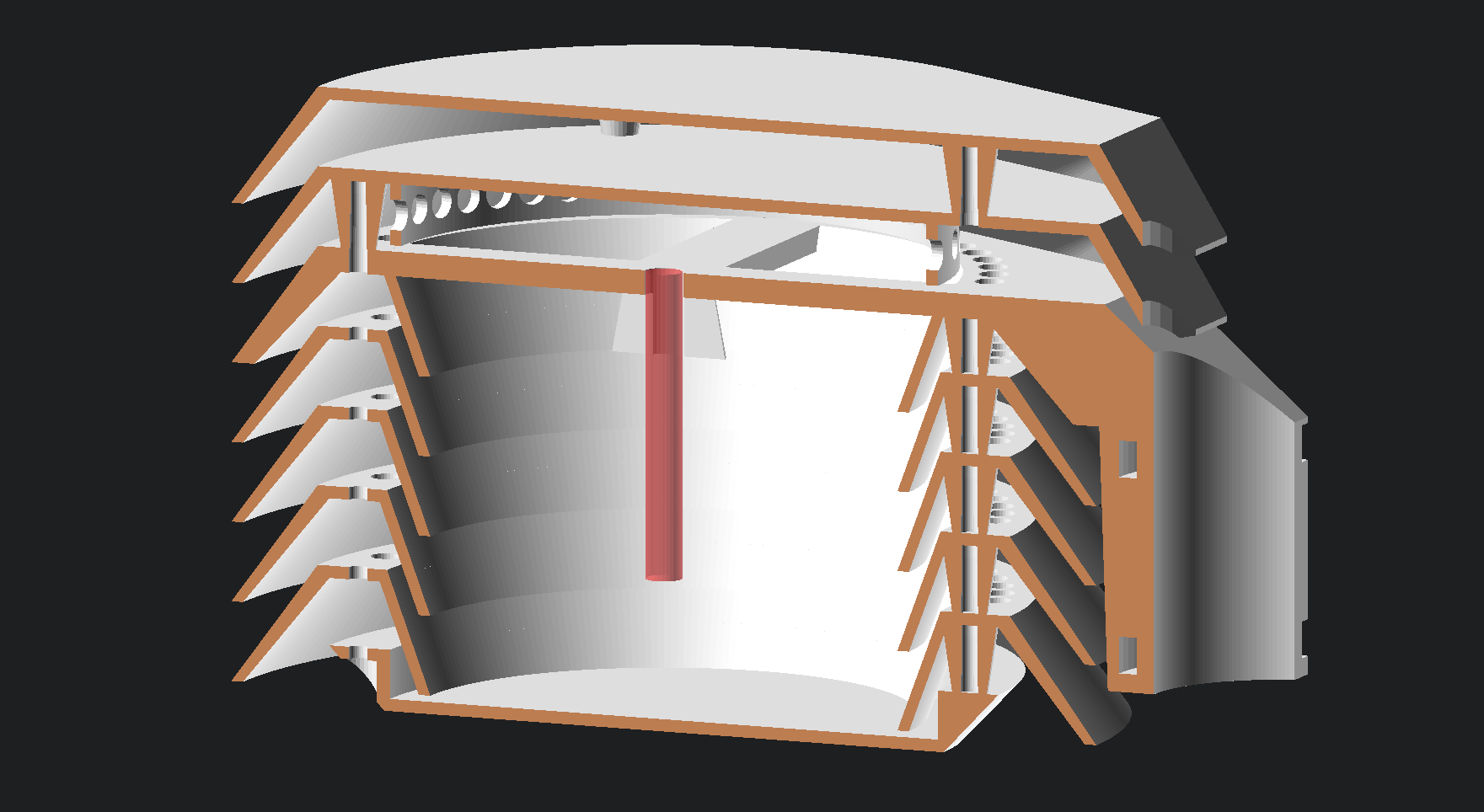

3D print Double sun shield for thermometer DS18B20

3D printed shield, against overheating of the thermometer in direct sunlight.

3D printed shield, against overheating of the thermometer in direct sunlight.

The doubling of the shield makes it possible to better shield the salve heat from the heated outer shield.

Source files on GitHub

Printables mirror

- I include the source file sun-shield.scad in OpenScad

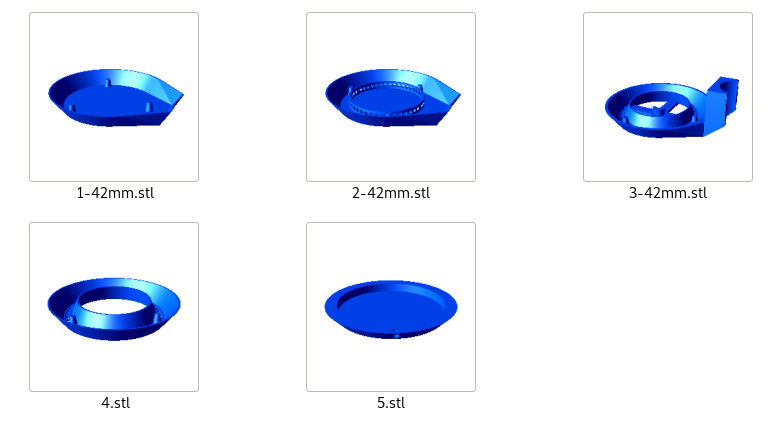

- exported .STL files for individual parts (preset for mounting rods with a diameter of 42 mm)

- preset .3mf files

BOM

You can use 3D printing to order, for example at mirex3d.cz - don't forget to specify the diameter of the mounting pipe.

Tools

How to change the diameter of the mounting pipe

- First step measure mouting pipe diameter

- Open source code in OpenScad and change line

MOUNTDIA = 42;

- Change the parameter gradually from 1 to 3

Part = 1;

then press F6 and F7 for .STL export this part. Other parts not depend to mounting pipe diameter.

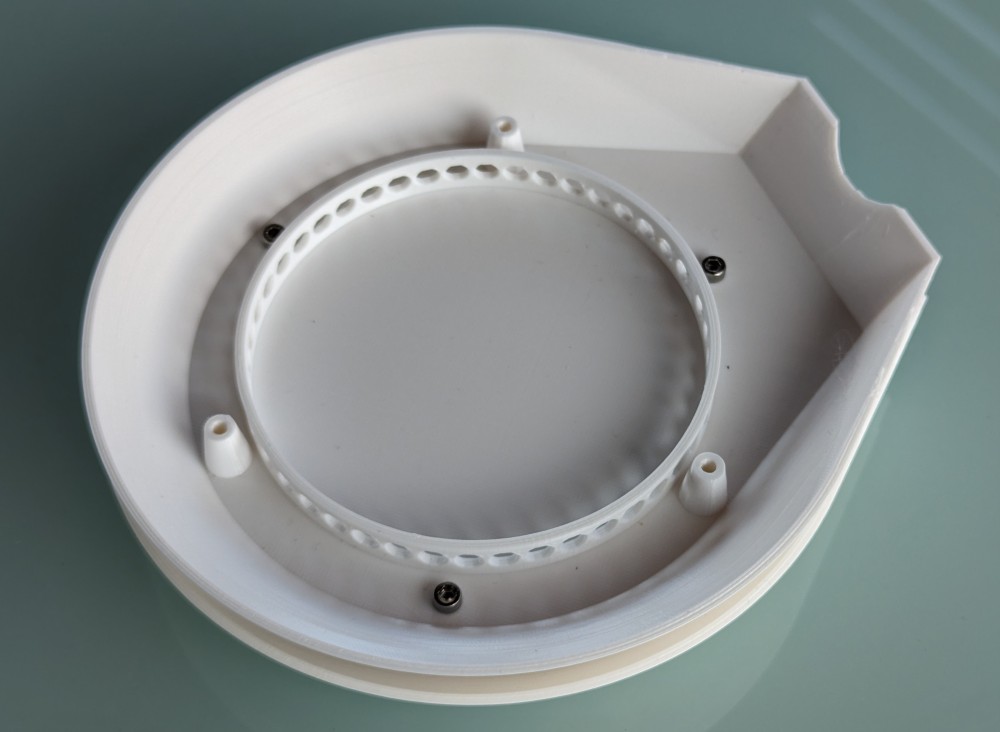

- After complete all STL parts you can start 3D printing with WHITE PETG filament. Sun-shield part nr 4 you print four times.

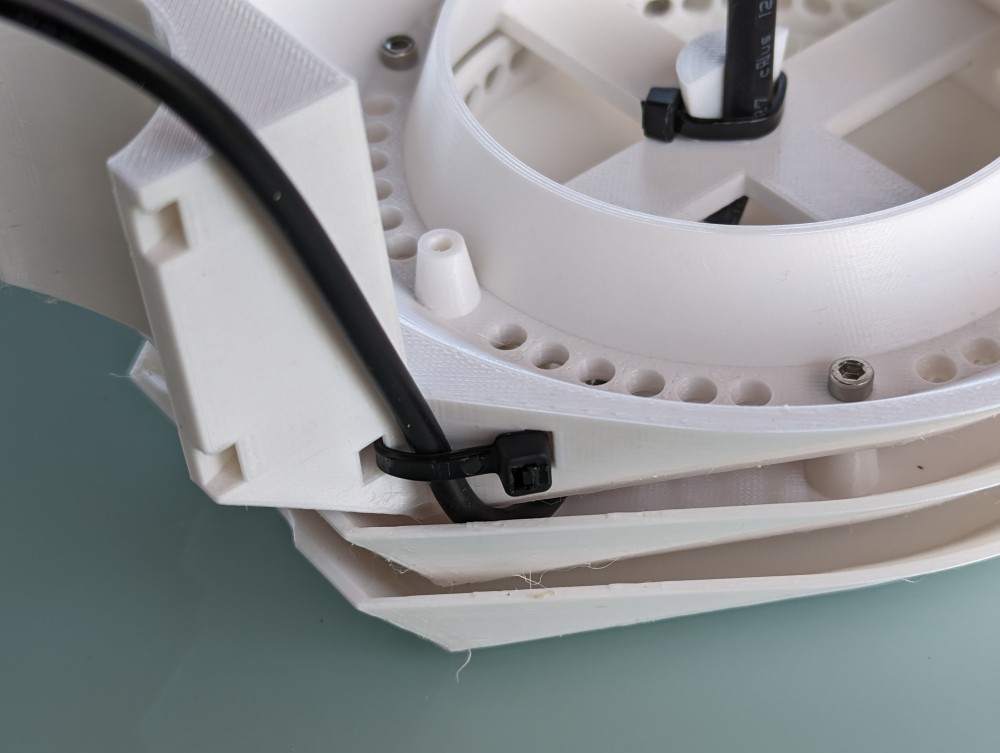

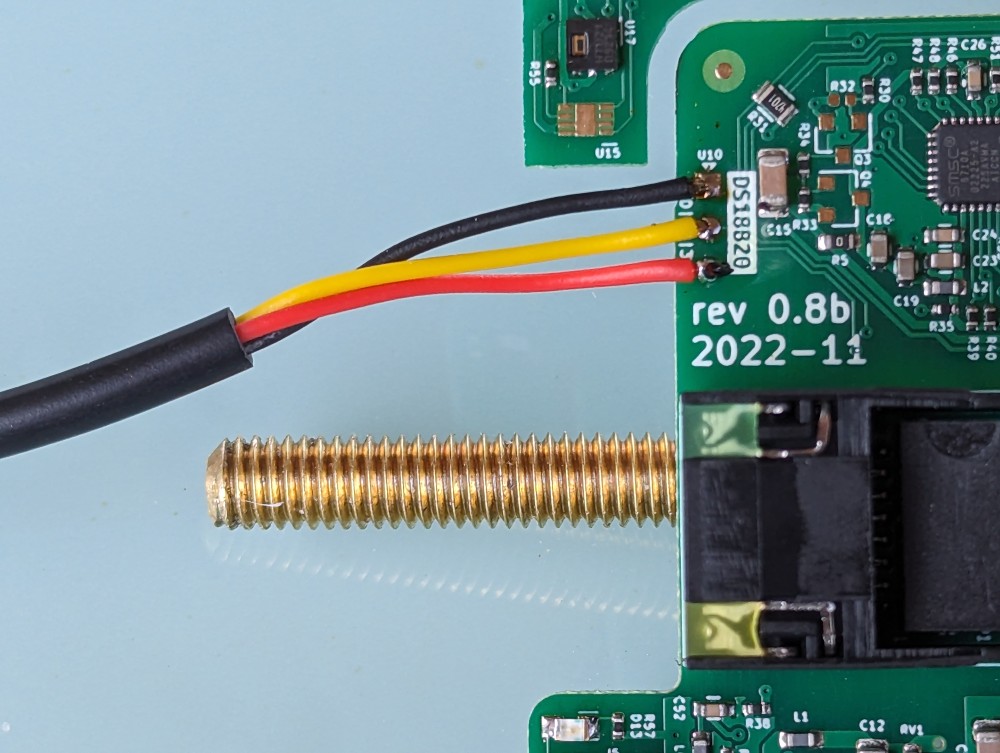

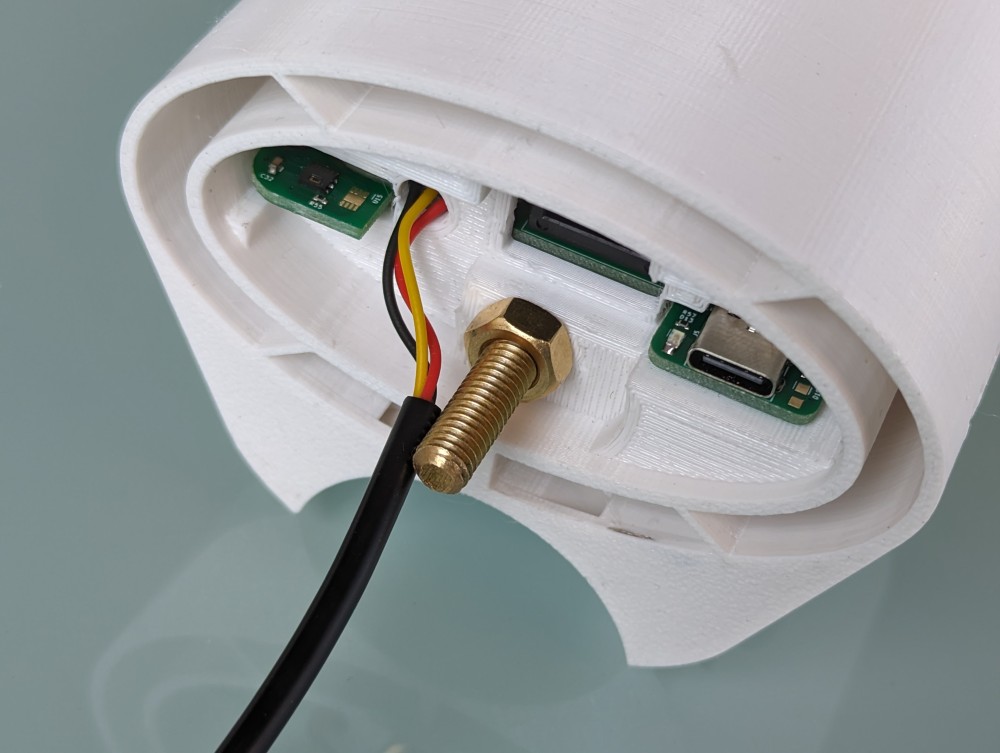

Assembly manual, step by step

Connected to a 3D print weather station

3D print WX station Wiki