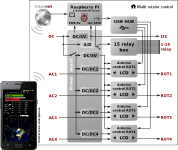

Web control four rotator, fifteen relays and many other features that come from Raspberry PI RemoteQTH server.

Developed for contest station "Policko" OL7M

Main functions:

- Control the four rotators using the light buttons,

rotary encoder and with a two-line display for each rotor. - Same control remoted via web interface or telnet

- only click to map and confirm rotating.

- Rotator module can directly control the motor of the rotator

- DC version of the phase-change

- AC version switching CW or CCW winding

- 24 freely configurable relay (15 in model B) (first used for server power on/off)

as single pole, single throw or single pole, more throw

- suitable for switching antennas.

- GPIO interface power board associating functions

- Relay switching from GPIO

- DC/DC converters power supply 5V for Raspberry PI

- DC/DC converters power supply 5V for four arduino rotators module.

Turns ON the first GPIO output. - Available four DC/DC converters - custom voltage power supply for each motor of rotator. In the range of 2 to 37V an max current 3A.

- Include A/D converter for four voltage measurement

- Expand I2C bus - available connect next temperature or voltage sensors

- All in simple 2U Rack case.

- Case made to measure from 2 mm aluminium.

- Laser engraving plastic front panel.

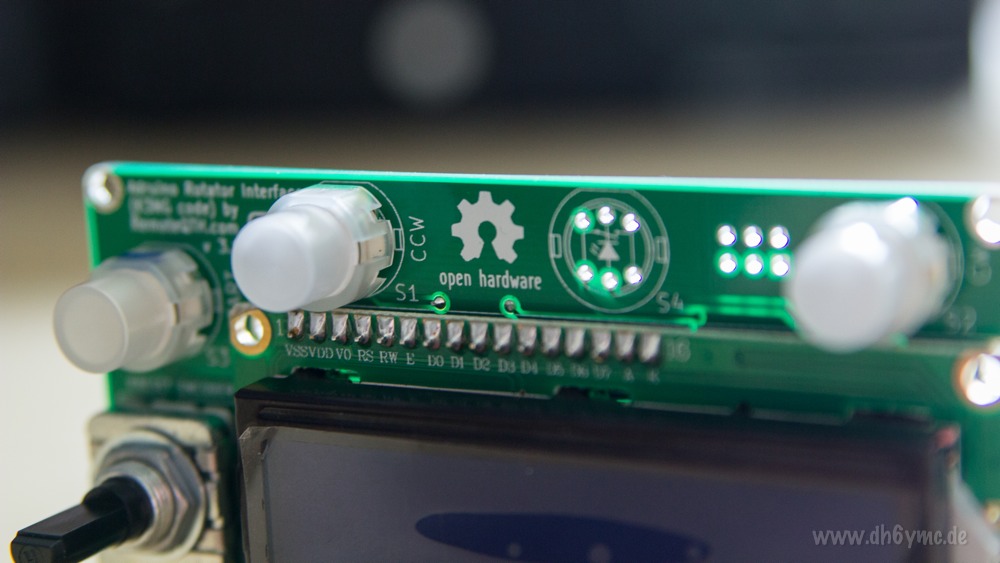

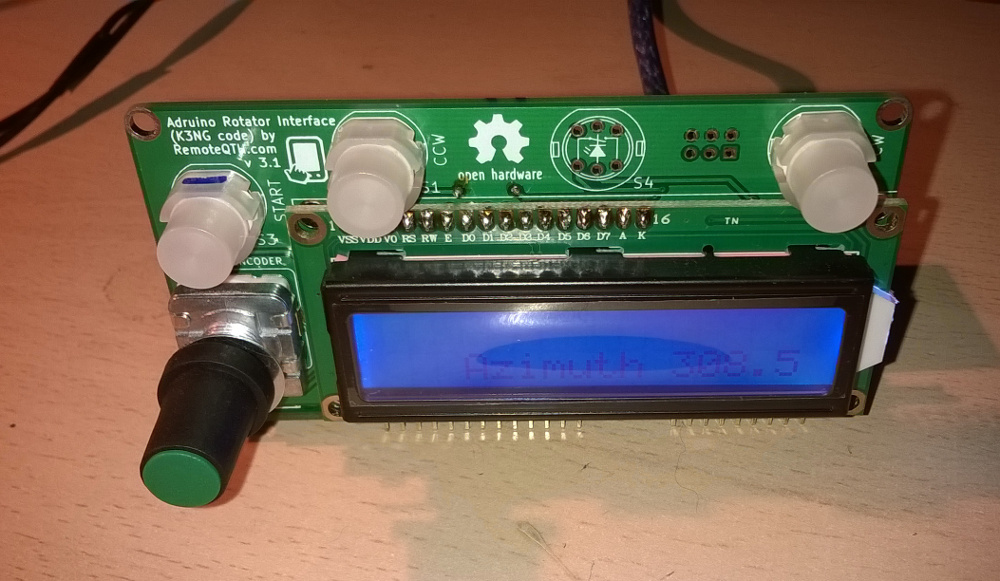

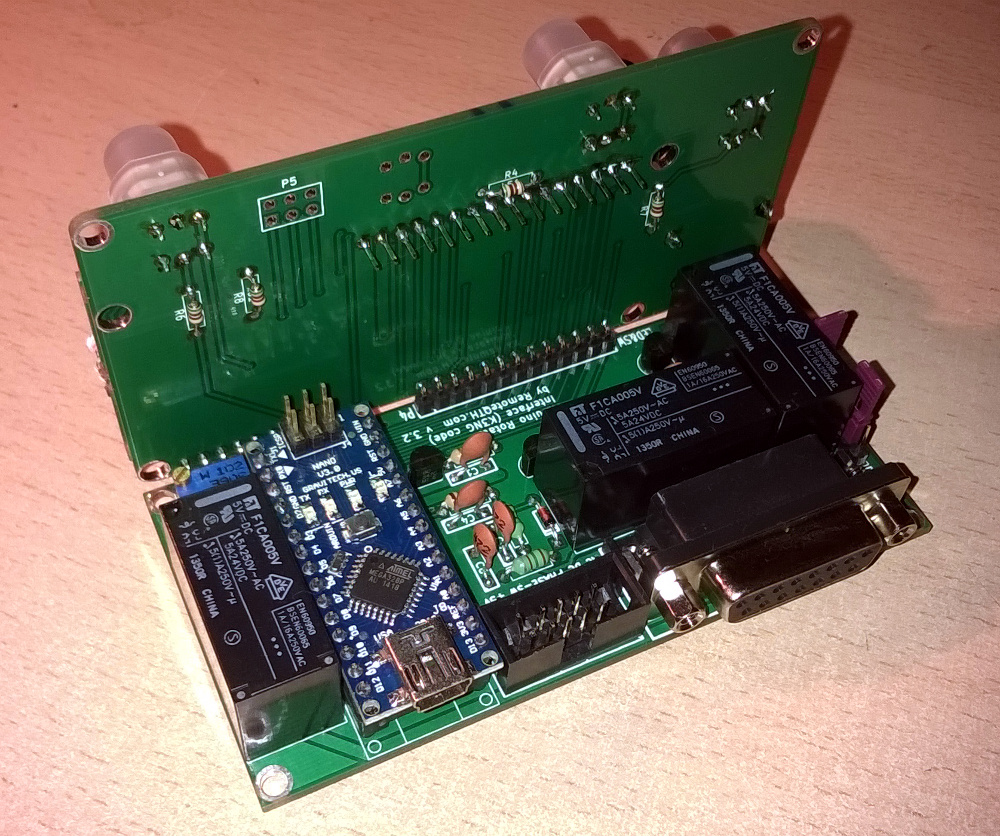

- Each the rotator unit interface, based on arduino (code by K3NG) contains:

- LCD.

- Lighting button (CW, CCW, Start).

- Preset encoder.

- Three relay (CW, CCW and Brake).

- Arduino nano module.

- Ready for AC and DC rotators.

- Analog input.

- 5V power voltage.

- Server requires a DC power supply ranging from 9 to 40 volts.

Voltage is dependent to the rotator, if we are powered motor directly from the server. - If you have a rotator AC motor, the server has terminals

for connecting the AC voltage for each rotor separately. - Another server utilization

- Necessary components

- Rack case.

- Rapsberry PI + 4GB SD card with RemoteQTH server.

- GPIO interface power board.

- Relay board.

- Four arduino rotator interface.

- Usb hub with external power supply.

- DC power supply 9-40V dependency to max DC rotator voltage.

- AC power supply if AC rotator instaled.

Block diagram (model B+)  |

GPIO Board circuit (model 2/B+)  |

Rotator control circuit  |

Block diagram (model B)  |

GPIO Board circuit (model B)  |

Unit test:

Download

| Rotator module PCB | |||||

|---|---|---|---|---|---|

| v3.3 | sch  |

front.brd  |

back.brd  |

kicad2940 | |

| v3.2 | sch  |

front.brd  |

back.brd  |

kicad935 | |

| v3.1 | sch  |

front.brd  |

back.brd  |

kicad956 | |

| v2 lcd | pcb  |

sch  |

eagle977 | ||

| v2 base | pcb  |

sch  |

eagle907 | ||

| Arduino firmware | |||||

| by K3NG | stable | unstable | doc | pins.h1562 | |

| Raspberry PI GPIO interface PCB | |||||

| Model RPI2/B+ v2.2 | sch  |

brd  |

kicad812 | wiki | |

| Model B+ v2.1 | sch  |

brd  |

kicad806 | ||

| Model B v1.2 | sch  |

brd  |

kicad753 | ||

| I2C temperature sensor PCB | |||||

| v1.0 | sch  |

front.brd  |

kicad799 | ||

| 2U rack case (19-inch x 2u (3.5") x 9.5") | |||||

| Version 6 | full.DXF808 | DXF4cutter847 | |||

| Version 4 | full.DXF921 | DXF4cutter911 | wiki | ||

| Front panel design (inkscape) | svg  |

||||

Open-Hardware Open-Hardware

|

|

||||

|

We believe open source is a better way of doing things. View and download the Shield Schematic and PCB Kicad/Eagle CAD files, LibreCAD .DXF, or Inkscape .SVG files. The hardware designs are released under the Creative Commons Attribution-ShareAlike 4.0 International License |

|||||

Users implementation

DH6YMC |

F4EGA  |

F4EGA  |